Rejuvenation

There’s no such thing as textile waste. Not if you can rejuvenate it.

Leading the textile industry towards a new future

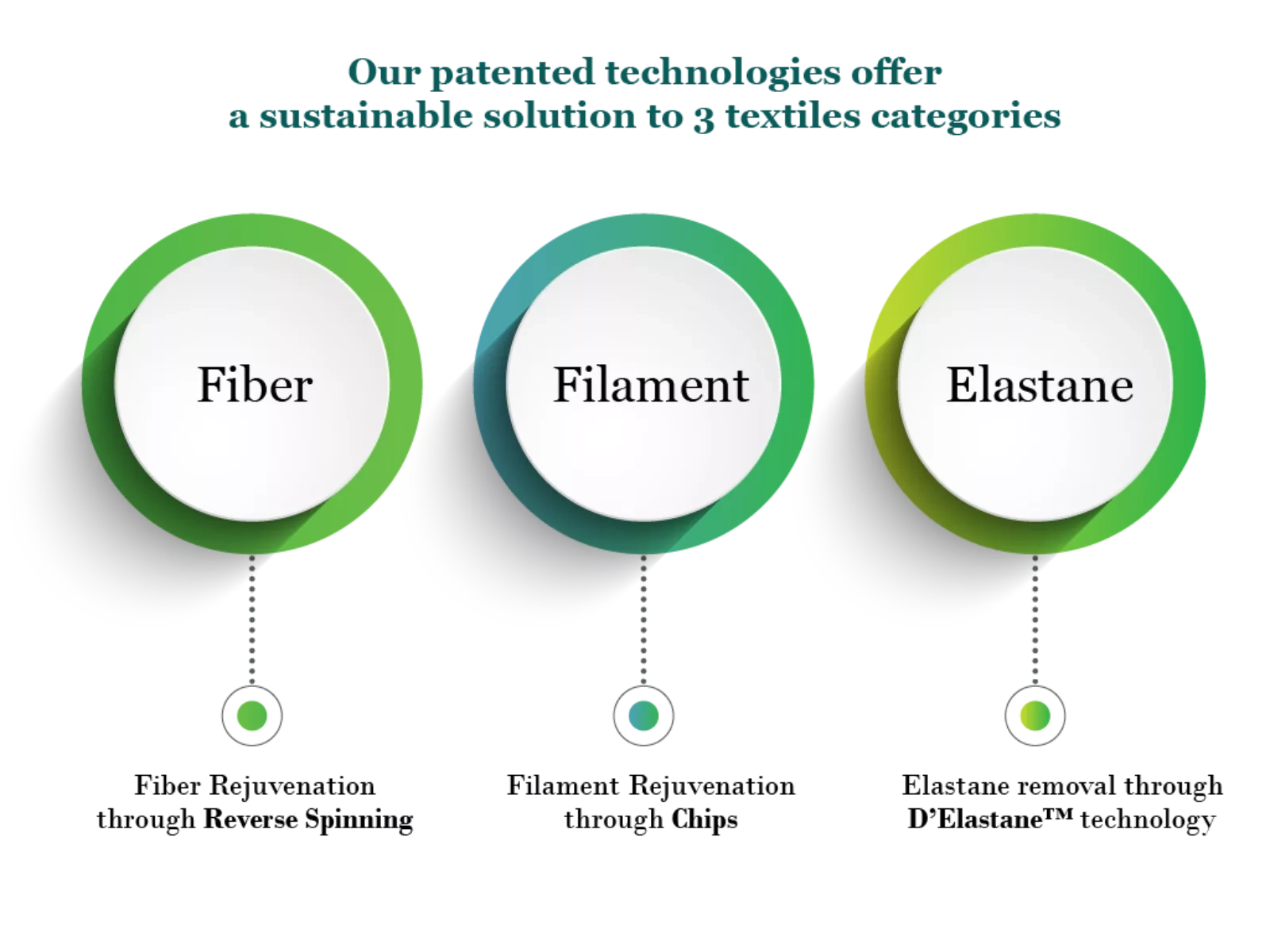

With more than 20 patents and 35 trade secrets related to textile rejuvenation, we have developed a unique method to collect and repurpose textile waste from all over the world. By maintaining the length and strength of each fiber, we can deliver high-quality products labeled Powered by Purfi that industry, partners, and consumers will love.

Cotton

Polyester

Cotton/Polyester Blend

Acrylic

Collection of fibers

It all starts with fiber. Instead of letting textile waste go to waste, Purfi collects a variety of materials from partners. This includes pre-consumer, post-consumer and post-industrial materials.

Modacryl

Aramids

Viscose

Aramids/Viscose Blend

Our Purfi Processes

Fiber Rejuvenation

1

Textile Waste Collection

2

Sorting and Quality Control

3

Reverse Spinning

4

Distribution & Production

Filament Rejuvenation

1

Textile Waste Collection

2

Sorting and Quality Control

3

Chips

4

Distribution & Production

D'Elastane™

1

Textile Waste Collection

2

Sorting and Quality Control

3

Elastane Removal

4

Distribution & Production

Textile waste collection

In order to rid the planet of textile waste, you’ve got to go where the waste is.

That’s why we have set up collection facilities in textile dense areas worldwide to lower transportation and resource costs, and ultimately, environmental impact.

Purfi trains supplier personnel and provides all the necessary tools to perform this task without interrupting production workflow.

Sorting and Quality control

Purfi collection protocols emphasize the segregation of waste materials according to vital criteria like color, composition, and finish, to name a few.

Our Quality Control measures are implemented at the collection centers to verify that materials received correspond to those collected from the manufacturing facilities. These criteria are essential in determining how the materials will be processed for the Purfi Partner in downstream rejuvenation.

We can custom blend materials from our extensive inventory to create products according to our Partner’s exact specifications.

What could be better than complete transparency to go along with Zero Waste in your supply chain?

Reverse Spinning

Purfi’s rejuvenation process is centered around the needs of our Partners.

We blend to your exact specifications at our collection facilities, upload the information to our rejuvenation system, and ship the bales to one of our rejuvenation facilities to be processed. Once there, the materials are manufactured according to a recipe specifically designed to produce original-quality fibers for your new creation.

Purfi does not use harsh, caustic chemicals nor overly aggressive machinery which tears the material during processing. Instead, we use patented Reverse Spinning technology to individualize fibers, then infuse them with eco-friendly liquid compound treatments, which are either organic or natural, to reinforce their structural integrity.

And we also sanitize all fibers with anti-microbial treatments to truly make pure fiber. All of this from 100% textile waste!

Distribution & Production

After rejuvenation by Reverse Spinning, fibers are sent back to our partners with a track and trace code. Every fiber batch is equipped with a tracker for its entire life cycle, so consumers can be assured to have 100% Purfi fibers.

As a brand or producer, you are now ready to develop a whole new range of products. And through showing your commitment to a sustainable and circular world, you will be Powered by Purfi.